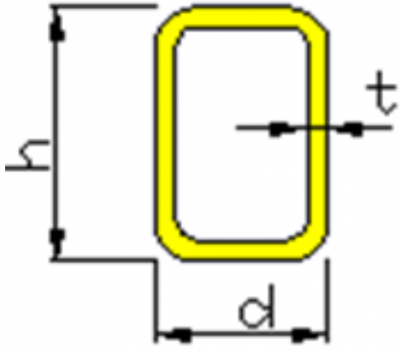

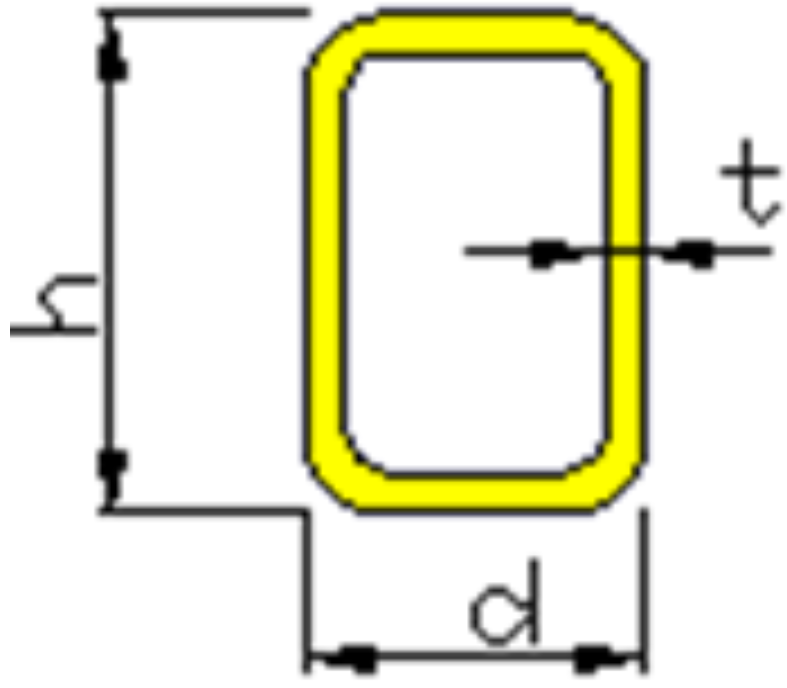

CFRHS pipes are usually made from carbon steel and are processed through a variety of methods, such as cold rolling, welding, and bending. This results in a strong and durable profile that can be used to build everything from retaining walls and fences to complex industrial frames.

Several factors distinguish CFRHS pipes from other commercial steels. They are relatively easy to process and shape, making them an ideal choice for customized projects. The advantages of CFRHS pipes over the HFRHS pipes include a better surface finish and lower production cost. Historically, the disadvantage of CFRHS pipes has stemmed from residual stresses in the material that can create problems, such as during welding.

Common uses for CFRHS pipes range from construction projects like fences, railings, retaining walls, and roof trusses, to industrial frames. They are also used in the manufacturing industry to create everything from shelving systems and storage solutions to various types of frameworks. Contact us today for more information about our CFRHS profiles.