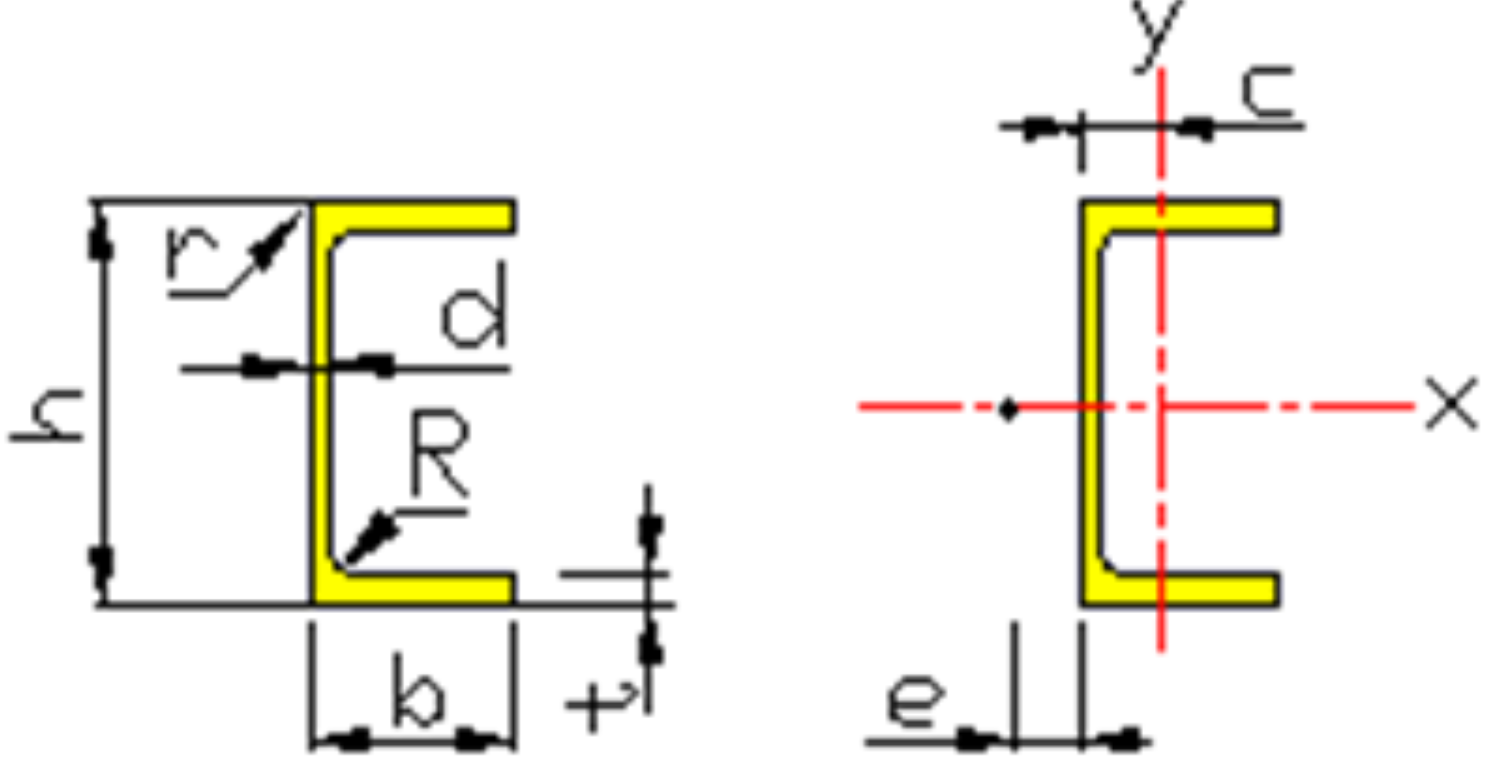

Our UPE beams are made of high-quality steel, which gives them high durability and good corrosion resistance. UPE beams offer a number of advantages. Thanks to their U-shape and parallel flanges, they offer a larger surface for connection, which can be an advantage in the construction of complex structures. They are also lighter than other beams of the same size, which can contribute to reduced transportation and installation costs. UPE beams are well suited for use as a complement to H-beams in areas with less load.

UPE beams are used in a variety of sectors, including the construction industry, machine manufacturing, bridge and tunnel construction. They are also popular in the construction of homes, offices, and other buildings, where their strength, durability, and efficiency are crucial. UPE beams offer a balance between performance, weight, and cost-effectiveness that makes them an attractive alternative in a variety of applications.